Products

TDP is specialized in turning casting components according to the client's technical drawings by processing the machining centers with the respective equipment and using advanced production and control systems for medium and large mechanical processes.

Processes

and Equipment

Considering the high dimensional accuracy required (micron), the company has also established itself in the last years by significantly increasing its machinery park with machine tools from the most precise and trusted tools available on the market (Emag, Mori-Seiki, Biglia).

Moreover, the company is dedicated to improve its processes continuously by optimizing its processing sequences and reducing the costs resulting from a lack of quality in order to deliver products which meet the client's plans.

Moreover, the company is dedicated to improve its processes continuously by optimizing its processing sequences and reducing the costs resulting from a lack of quality in order to deliver products which meet the client's plans.

Quality Control

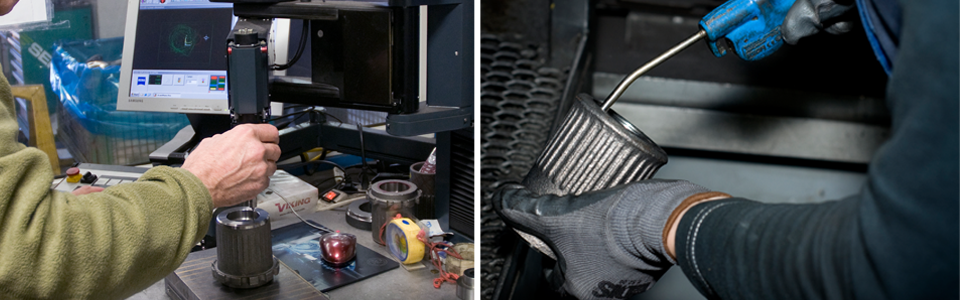

Every production sequence at TDP is subject to controls regulated by the processing and control cycle. These controls are characterized by a dimensional control of 100 % of the processed diameters by means of Marposs air plugs.

The controls are furthermore completed with a technical approval to be issued before the productions starts and to be executed by a test performed with a Zeiss 3D measuring machine connected to a computer which is used for the measuring program and data storage.

The controls are furthermore completed with a technical approval to be issued before the productions starts and to be executed by a test performed with a Zeiss 3D measuring machine connected to a computer which is used for the measuring program and data storage.